Microlattice

Microlattice is an ultra-light metal material formed of a nano-scale tube lattice structure. It is one of the lightest existing structural materials, with a density of 0.9 mg/cm3 (0.00561 lb/ft3).[1] Microlattice has many potential practical applications in several industries and technologies such as aerospace, automotive, armor systems, and architectural uses.

Properties

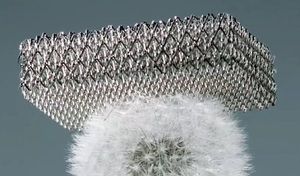

Microlattice is composed of a nickle-phosphorus alloy arranged in a lattice structure of hollow tubes. Each strut tube has a wall thickness of about 100 nanometers (about 1,000 times thinner than a human hair) [2] These tubes help absorb impacts by distributing force over a greater surface area in a focused area on the lattice’s outer surface. This type of structure is very comparable to the complex design that can be observed in many bones.

Microlattice is reported to be about 100 times lighter than styrofoam, yet as strong as titanium (which is twice as strong as steel per weight). [3] It is, in fact, so light it can sit atop a dandelion without disturbing it’s seed bundles. It can recover it’s shape after pressures exceeding 50% strain. [4] The material absorbs shocks so well that researchers say a chicken egg wrapped in a layer of microlattice could survive a fall from the roof of a 25 story high building without cracking.[5]

History

Microlattice was developed by HRL Laboratories (a research company owned by Boeing) in colaboration with researchers at Caltech, Irvine, and University of California. [6] It was first publically anounced in November 2011. [7] In 2012, Popular Mechanics declared Microlattice as one of 10 World-Changing Innovations.

Production

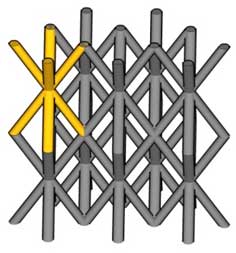

Microlattice is produced by creating a polymer skeletal structured template the shape of the lattice. This template is formed by passing UV light through a perforated mask into a reservoie of UV curable resin. Resin cures under each hole of the mask, forming a polymer fiber along the path of the light. By using several light beams, multiple fibers could then interconnect to form the lattice structure. The template can be formed within 10-100 seconds, making the process efficient and scalable. The template is then coated with a thin layer of a nickel-phosphorus alloy. The temporary inner resin template structure is then etched away, leaving the final microlattice material.

Potential Applications

Microlattice may be used for it’s great shock absorption qualities for various forms of personal protection gear such as crash helmets, and police and military applications in body armor systems. Microlattice and similar materials may also be useful for battery electrodes due to it’s great surface area to volume ratio. It may also be used for an advanced energy storage system due to it’s spring-like compression abilities. Microlattice is also being considered by automotive and aeronautical manufacturers to develop extremely lightweight and efficient structures that combine multiple functions such as structual reinforcement and heat transfer into single components for high-performance vehicles.

Similar Materials

A similar but denser material was created by researchers at the University of Toronto in 2008, consisting of an electrodeposited nanocrystalline nickel layer over a polymeric rapid-prototyped truss. Other materials similar in that they are composed of microlattices similar to the lattice structure of Microlattice are the carbon based materials: aerographite and aerogel.

Footnotes

- ↑ https://newatlas.com/ultralight-micro-lattice-material/20537/

- ↑ https://en.wikipedia.org/wiki/Metallic_microlattice

- ↑ https://theweek.com/articles/582787/metal-light-styrofoam-strong-titanium--5-other-amazing-new-materials

- ↑ https://futurism.com/meet-the-worlds-lightest-metal-its-99-99-air-2/

- ↑ https://futurism.com/meet-the-worlds-lightest-metal-its-99-99-air-2/

- ↑ https://futurism.com/meet-the-worlds-lightest-metal-its-99-99-air-2/

- ↑ https://futurism.com/meet-the-worlds-lightest-metal-its-99-99-air-2/